DinaSoft Software Engineering Group

Provider of Industrial Software Solutions

DinaSoft Software Engineering Group, with a focus on increasing productivity and reducing costs in industries and organizations, has been involved in designing and developing software platforms. In this regard, and based on the needs of various industries, the group has successfully developed high-performance software solutions using the expertise of its young specialists.

MRP II

MOTOR AZMA

The Design and Development Process of Dinasoft Software Group Projects

Technical Review and Requirement Analysis

In the initial stage, your specific needs and technical considerations are reviewed and analyzed. This ensures that the software design process aligns with your objectives. Any identified challenges or constraints are addressed, and the most suitable solutions are provided to meet your requirements.

Preparation of Your Requirements Document

In this phase, all functional and non-functional requirements of your software are documented and formalized. This includes recording detailed information about the desired features, performance expectations, scalability needs, security requirements, and other essential specifications necessary for the successful implementation of the software.

Designing the Software User Interface by the UI/UX Team

In this phase, the UI/UX team focuses on creating an engaging and user-friendly interface for the software. The process includes designing initial wireframes, developing the final layout of the software interface, and implementing the customer requirements document to ensure an optimal user experience. Clients are kept informed of the design process details and can provide feedback or suggestions as needed.

Software Development by the Programming Team

In this phase, software development begins based on the UI/UX team’s design and final approval from the clients. At each stage of development, the project is evaluated by the testing team, and identified issues or bugs are resolved. After the software successfully passes all testing phases and fully meets the client’s requirements, it will be ready for complete delivery to the client.

Final Project Delivery

After completing the software development process, the project is delivered to the client. This phase includes deploying the software on the client’s internal servers or cloud infrastructure, installing necessary equipment, configuring the system, and providing any required training or support.

DinaSoft software company services

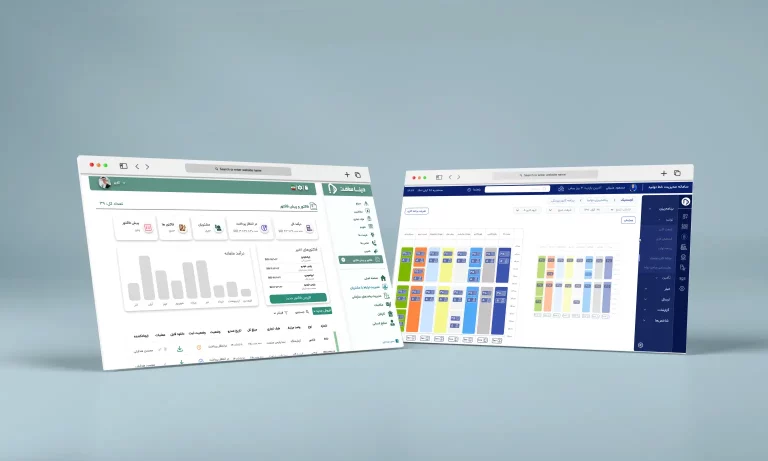

Designing specialized and practical software

Dina Soft Software Engineering Group is a producer of general, specialized and practical software under the web, Windows and mobile applications. Our functional and specialized software helps businesses to streamline operations, maximize efficiency and achieve their goals.

Application design

Production line monitoring application

The production line monitoring application allows you to monitor the production status and performance of your equipment in real time from anywhere. With a modern design and simple user interface, this application helps you to easily access critical panel data and make better decisions to improve efficiency and reduce costs.

Key features of the application:

-

Real-time monitoring:

Viewing the status of production and performance of equipment live and at any time

-

Advanced reporting:

Generating comprehensive and detailed reports of production line performance and identifying weak and strong points

-

Smart Alerts:

Receive instant alerts in case of problems or need for repairs

-

Remote access:

Ability to access data and control equipment from any location using mobile devices

-

User friendly interface:

Simple and modern design that makes the application easy for all users

This application allows you to always be one step ahead of problems and react quickly to changes.

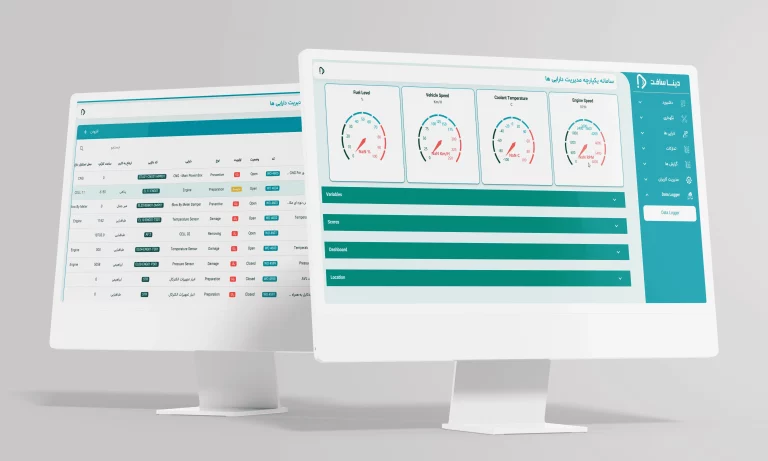

Monitoring system and Internet of Things (IOT)

Production of products for monitoring and connecting equipment to each other and the data center, in this regard, manufacturers and craftsmen can monitor their equipment and production line more actively using IoT technology. In the maintenance management system (CMMS), you can use this technology to know the status of equipment and production lines online and in real time, and in case of any technical problem, the system will quickly check the equipment by sensors and continue until the operator makes a decision. Stops the process.