Author:

Mohsen Shamsi

Category:

Articles

Study time: 15 minutes

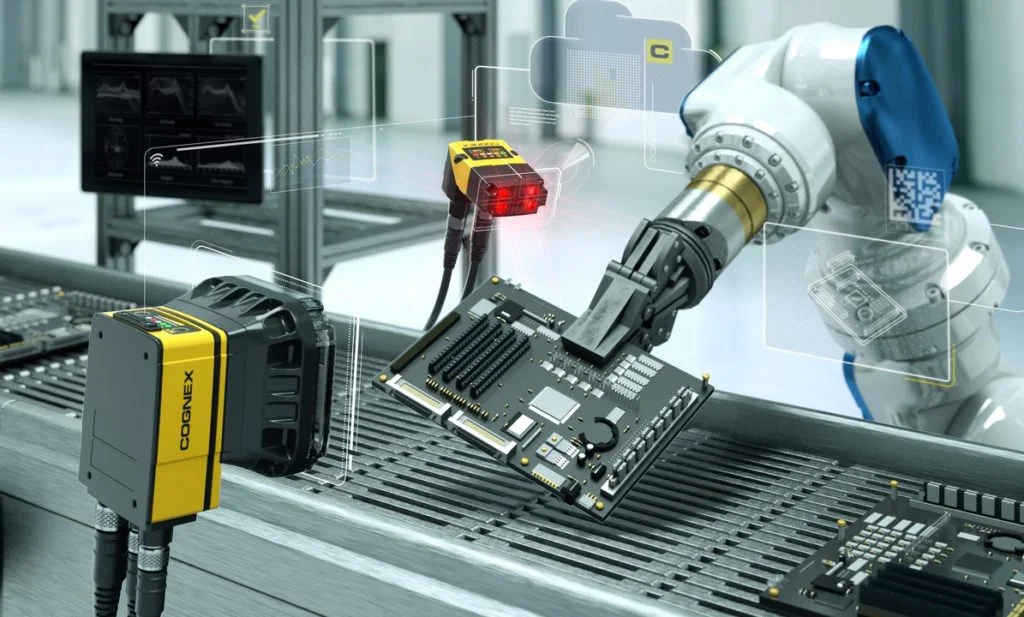

Machine vision is a branch of artificial intelligence and computer engineering that allows systems to see and understand their surroundings using cameras and image sensors. The main purpose of machine vision is to process and analyze images to extract useful information. This technology is used in many areas, including:

Recognition and identification of objects in images such as face recognition, license plates, or products in production lines.

To check and accurately measure manufactured products and ensure their quality.

In industrial robots to perform tasks such as object sorting, mapping, and navigation.

To diagnose diseases from medical images such as MRI, CT scan and X-ray.

To identify the environment, obstacles and navigation.

Machine vision works with the help of image processing techniques, deep learning, artificial neural networks and complex algorithms. Systems use image, video or 3D data and convert it into usable digital information.

Machine vision is a scientific and technological field that allows computer systems to understand their surroundings by observing and analyzing images and make decisions or take certain actions based on them. In short, machine vision is a process where computers act like an “eye” and see images, but beyond human vision, by analyzing and processing them to extract useful information.

For a more complete explanation, this process can be divided into the following steps:

In the first step, the machine vision system collects image data through various sensors (such as digital cameras, laser sensors or infrared cameras). These data can be two-dimensional or three-dimensional images. The quality and type of these images depends on the specific application of machine vision. For example:

2D images: used to recognize faces or scan products in production lines.

3D images: They are used in robotics and self-driving cars to map the environment and identify objects in real space.

At this stage, the raw images received by the camera or sensor are prepared for analysis. This pre-processing includes image quality improvement, noise removal, contrast adjustment and light optimization. Some of the preprocessing techniques are:

Filter images to remove unnecessary noise.

Adjust brightness and contrast to make image details clearer.

Convert to black and white images to reduce processing complexity.

In this step, the system extracts key information and features such as edges, shapes, patterns, colors or textures from the processed images. These features play a vital role in recognizing and classifying objects. Feature extraction turns the image into data that can be understood and analyzed by artificial intelligence algorithms.

Here, machine learning or deep learning algorithms are used to compare the extracted features with pre-trained information and recognize the desired object. For example, if the goal is face recognition, the face recognition algorithm determines the person's identity based on the facial features extracted from the image.

At this stage, the system makes a decision based on the analysis and processing done and provides the appropriate output. This output can be in different forms:

Announcing the results: for example, identifying the object or its position in the image.

Operational control: Sending a signal to execute an action, such as stopping a production line if a defective product is detected.

Creating new data: For example, in self-driving cars, this information is used to decide which way to go or stop when encountering an obstacle.

This step is present in some systems that use continuous learning. Based on previous feedback and experience, the system can improve its algorithms and increase its accuracy.

Machine vision is used in many industries and fields:

In production lines, machine vision systems are used to inspect and control the quality of products. These systems are able to detect small defects that may be ignored by humans and act quickly.

In medical science, machine vision is used to diagnose diseases and analyze medical images such as MRI, CT scan and radiology images. These systems can accurately detect abnormalities and help doctors make better decisions.

In self-driving cars, machine vision plays a vital role. These systems allow cars to see their surroundings, detect obstacles and choose the right path. Cameras and sensors installed on the car acquire images of the environment and analyze them to make decisions in the moment.

In the field of security and surveillance, machine vision is used in CCTV cameras and facial recognition systems to identify suspicious people or objects.

In agriculture, machine vision systems help farmers to carefully monitor the condition of plants and crops and make appropriate decisions based on image data to improve plant growth and increase productivity.

Several technologies and tools play a fundamental role in machine vision:

Digital image processing includes techniques such as filtering, transformations, and image analysis that help improve and extract information from images.

Machine Learning Machine learning algorithms are used to recognize patterns and classify data in machine vision.

Deep neural networks (Deep Neural Networks) These networks allow systems to learn from a large amount of image data, to find the ability to recognize and analyze images better. This technology is especially used in complex applications such as face or object recognition.

Despite great advances, machine vision still faces several challenges:

Accuracy in poor lighting conditions: Changes in light can reduce the accuracy of car vision systems.

Data complexity: 3D images and data are large and require fast processing.

Accurate detection in complex environments: Systems may have difficulty making decisions in environments with complex obstacles or details.

Machine vision has several advantages that have made it one of the key technologies in various industries. Below we mention some of the most important advantages of machine vision.

Machine vision systems are very accurate in analyzing images and can identify small details and anomalies that humans may overlook. This high accuracy is especially important in sensitive industries such as the production of medical equipment or electronic products. Reducing human errors ultimately leads to improving the quality of products and services.

Machine vision can process images at a very high speed, which makes various processes, especially in industrial production lines, much faster and more efficient. The use of this technology can increase productivity, reduce inspection time, and optimize production.

In some environments that may be dangerous for humans or have unfavorable environmental conditions (such as high temperatures, toxic conditions, or dark environments), machine vision systems can function effectively. These systems do not need to rest or stop and can work continuously in these conditions.

Using machine vision in industrial and manufacturing processes can reduce labor costs, manual inspection time, and human errors. Also, by reducing the amount of defective products, the costs of waste production are also greatly reduced. As a result, employers can achieve significant savings in the long term by investing in this technology.

Machine vision systems can perform tasks repeatedly with the same accuracy and quality, while human performance may be affected over time by fatigue or environmental changes. This high repeatability is especially useful in processes that require frequent inspections.

Machine vision systems with high accuracy and the ability to identify small problems in production help to improve the quality of products. These systems are able to detect manufacturing defects such as cracks, scratches, color changes and unusual sizes that may be overlooked in manual inspection.

Machine vision can process images in real time and provide results immediately. This feature is very useful in industries that require continuous monitoring, such as production lines, traffic control or self-driving cars. This quick analysis can help make immediate and effective decisions.

In some hazardous environments, such as mines or industrial workshops with toxic materials, the use of machine vision can help improve safety. These systems can quickly detect accidents or anomalies, issue necessary warnings and prevent accidents from happening.

Machine vision can be used to identify problems in equipment before failure occurs. These systems can detect early signs of technical malfunctions and alert operators, enabling preventive maintenance and preventing unexpected breakdowns.

Machine vision can be used in various industries and can be configured for different applications such as face recognition, quality control, measurement and object recognition. This flexibility allows systems to easily adapt to changing needs and tasks.

By improving the quality of products and reducing the number of defective products that are released to the market, customers will be more satisfied with the products. This leads to the improvement of brand reputation and increase of customer loyalty.

In general, machine vision improves quality, increases productivity, reduces costs, improves safety, and enhances industrial and business processes. Its ability to perform tasks continuously, with high accuracy and without the need for human intervention, makes this technology one of the important tools in automation and digitalization. Processes have changed.

As a result, machine vision, as one of the advanced technologies in the field of artificial intelligence and industrial automation, offers significant capabilities in improving processes and increasing productivity. This technology helps businesses and industries improve their performance and reduce operating costs by providing high accuracy, fast processing speed, reducing human errors, and the ability to work in harsh environmental conditions.

Also, high repeatability and real-time analysis make it a vital tool for the manufacturing, medical, automotive, and security industries. Machine vision not only improves the quality of products, but also increases safety and prevents possible failures.

In general, with the rapid development of technology and deep learning, machine vision is expected to become an integral part of digital transformation in various industries and its applications will be increasingly expanded.

By entering your email in this section, you will find out about the latest articles published on the site

education

Articles

New

Tehranpars first square, Maleki St., 46, Unit 4

info@dinaeam.com

برای استفاده از دمو نرم افزارهای دینا فرم زیر را تکمیل فرمایید.