Study time: 10 minutes

The future of smart manufacturing using new technologies

Intro

The world is on the verge of a new industrial revolution, known as Industry 4.0, driven by emerging technologies and the smartization of manufacturing processes. In the past, manufacturing was largely based on human labor, mechanical assembly lines, and traditional systems. But today, with significant advances in artificial intelligence, the Internet of Things, robotics, and big data analytics, a concept called smart manufacturing is becoming the new standard in global industry. This type of manufacturing not only increases productivity and reduces costs, but also allows for product customization, predicting problems, and responding quickly to market changes.

۱٫ Industrial IoT

One of the main pillars of smart manufacturing is the Industrial Internet of Things. By installing sensors on equipment and machinery, this technology allows manufacturers to monitor vital data such as temperature, pressure, energy consumption, and machine performance in real time. This data is then sent to central or edge systems and analyzed with the help of intelligent algorithms. The result is rapid problem detection, prediction of failures, and prevention of sudden stops in production lines, which is highly effective in reducing costs and increasing productivity.

۲٫ Artificial Intelligence and Machine Learning

By analyzing vast amounts of data collected during the manufacturing process, AI can identify hidden patterns, potential defects, and opportunities for optimization. For example, AI-based machine vision systems can accurately inspect product quality, while machine learning algorithms can adjust the manufacturing process to minimize waste. At a higher level, AI can provide models for forecasting market demand and inventory management.

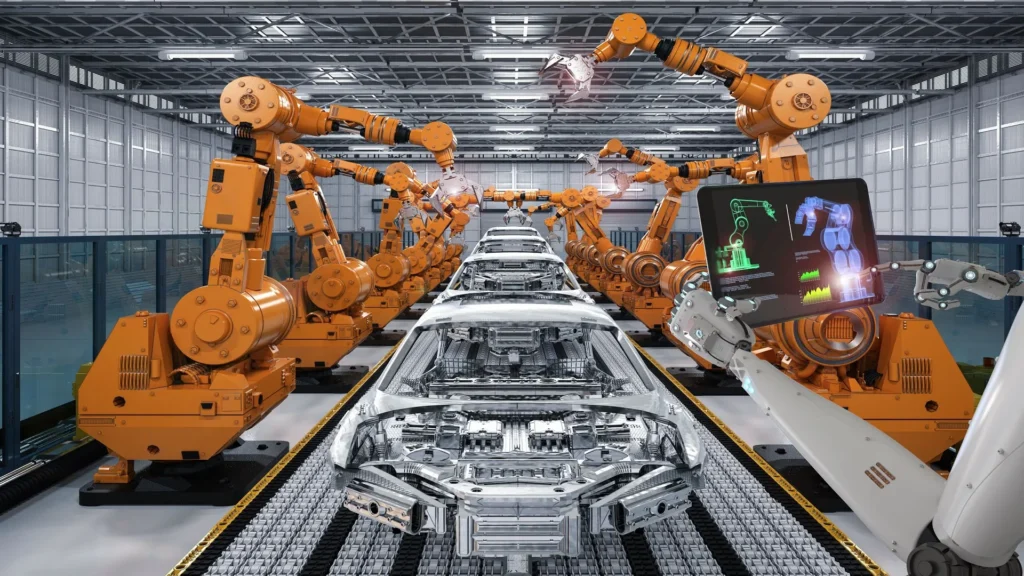

۳٫ Advanced robotics and human-robot collaboration (Cobots)

In smart manufacturing, robots do not just work independently, but also work alongside humans and in an interactive way. Collaborative robots (Cobots) are designed to work in shared environments with humans, without posing a risk to employee safety. These robots can perform repetitive, heavy or dangerous tasks, and move humans to more complex and analytical activities. This approach both increases productivity and provides a safer working environment.

۴٫ Cloud and Edge Computing

One of the main challenges in smart manufacturing is processing huge amounts of data in real time. Cloud computing allows this data to be stored and analyzed in cloud infrastructure, while edge computing enables faster responses by processing data closer to the source of production (e.g., in the factory or on the same machine). This combination enables greater flexibility, faster response to problems, and higher information security.

۵٫ ۳D Printing (Additive Manufacturing)

۳D printing is a key tool for creating custom products, complex designs, and rapid prototyping. Using this technology, parts with geometric structures that are impossible for traditional methods can be produced. This not only reduces the consumption of raw materials, but also reduces production time and costs associated with tooling. In the near future, manufacturing will move towards mass customization, and 3D printing is the key to this transformation.

۶٫ Blockchain in the supply chain

Blockchain technology, as a decentralized ledger, enables transparency and accurate traceability in the supply chain. In smart manufacturing, this technology can be used to ensure the authenticity of raw materials, track production processes, and maintain transparency in interactions with suppliers and customers. This transparency increases trust in the market and paves the way for sustainable and ethical trade.

Internet of Things and Artificial Intelligence in the Manufacturing Industry

New Trends in Manufacturing: Focus on IoT and Artificial Intelligence

As technology advances, the manufacturing industry, like many other sectors, is undergoing profound transformation. At the center of this transformation are two key technologies: the Internet of Things (IoT) and artificial intelligence (AI). These two technologies not only help optimize production processes, but also increase productivity, reduce costs, improve product quality, and provide flexibility in responding to market needs.

🌐 Internet of Things (IoT) in manufacturing:

Industrial IoT (IIoT) means connecting machinery, equipment, tools, and even raw materials to a smart network that collects and transmits information in real time.

Key benefits and applications of IoT in industry:

۱٫ Real-time monitoring and control of equipment:

Sensors connected to devices can monitor parameters such as temperature, pressure, vibration, and energy consumption in real time and send the information to the central system.

۲٫ Predictive Maintenance:

Instead of repairing after a failure, analyzing data from sensors can predict when a failure will occur and schedule repairs. This reduces production line downtime and extends the life of equipment.

۳٫ Smart resource and energy management:

IoT data helps factories monitor and optimize energy consumption, which leads to both cost savings and reduced environmental impact.

۴٫ Traceability and transparency in the supply chain:

Through sensors and smart tags, the path from raw materials to the finished product can be tracked. This is crucial for inventory management, quality control, and customer trust.

🧠 Artificial Intelligence (AI) in Manufacturing

Artificial intelligence, with its ability to learn from data and make intelligent decisions, is one of the determining factors in the transformation of the manufacturing industry.

Important applications of AI in manufacturing:

۱٫ Advanced Data Analysis (Advanced Analytics):

Smart factories generate massive amounts of data every day. AI analyzes this data and identifies hidden patterns, weaknesses, and opportunities for improvement.

۲٫ Machine Vision:

Vision systems equipped with artificial intelligence can detect tiny defects and flaws in manufactured parts with very high accuracy; much more accurately and faster than human labor.

۳٫ Decision-making automation:

AI can make decisions based on production data, such as automatically adjusting the production line, prioritizing orders, or suggesting changes to production formulas.

۴٫ Digital Simulation (Digital Twin):

AI combined with IoT can create a virtual version of a factory or product to predict how the system will perform under different conditions. This simulation helps to see the impact of changes before they are made in real life.

۵٫ Chatbots and virtual assistants for factory management:

AI can play a role in answering employee questions, monitoring production status, or even training new employees.

Advantages of the Internet of Things (IoT) in the manufacturing industry:

Industrial IoT (IIoT) refers to a network of devices, machinery, sensors, and software that are connected and exchange information with each other via the Internet. The use of IoT in industry has significantly increased productivity and improved quality.

✅ ۱٫ Increase operational efficiency

By connecting machines and tools to the network, their performance can be monitored in real time. This information allows managers to quickly react to problems or optimize processes. The result is reduced downtime and increased production speed.

✅ ۲٫ Predictive Maintenance

Sensors collect data such as vibration, temperature or pressure from machine parts. Data analysis algorithms analyze this information and issue warnings before a part fails. This:

Prevents sudden production stops,

Reduces repair costs,

Extends the life of the equipment.

✅ ۳٫ Reducing energy and resource consumption

IoT sensors measure the consumption of electricity, water, gas, or even raw materials in real time. This information helps engineers optimize consumption and minimize resource waste.

✅ ۴٫ Improve employee safety

IoT systems can intelligently detect hazardous conditions such as gas leaks, excessive temperature increases, or abnormal machinery movement and automatically alert or respond. As a result, workplace safety is enhanced.

✅ ۵٫ Transparency in the supply chain

With the help of tags, barcodes and GPS sensors, the movement of raw materials, semi-finished products and finished products can be precisely tracked. This is very useful for quality control, combating counterfeiting and optimizing inventory management.

Advantages of Machine Vision in Manufacturing

Machine vision is a branch of artificial intelligence and image processing that gives machines the ability to see, analyze, and make decisions. In various industries, machine vision is used for quality control, traceability, safety, and automation.

✅ ۱٫ Automatic and precise quality control

Machine vision systems are able to inspect products on the production line and detect any defects, lines, scratches, incorrect colors or measurement errors. Unlike humans, these systems:

do not get tired,

have the same accuracy,

check dozens of images per second.

✅ ۲٫ Increase production speed

Machine vision greatly speeds up the inspection process. When manufacturing is done on a large scale, manual inspection is time-consuming and costly; but with machine vision, products are inspected at high speed and without stopping.

✅ ۳٫ Improve product tracking and identification

Vision systems can read barcodes, QR codes, or even specific patterns on products and inform the production management system. This application is of great importance in the pharmaceutical, food, and component manufacturing industries.

✅ ۴٫ Increasing safety in the workplace

Machine vision, combined with surveillance cameras, can detect and alert the movement of employees, the path of machinery, or even unauthorized persons entering hazardous areas. These systems can significantly reduce workplace accidents.

✅ ۵٫ Ability to learn and adapt to changes

Modern machine vision systems use machine learning algorithms, meaning they can adapt to changes such as lighting, camera angle, product type, or even a new production model, and maintain their performance accuracy.

Conclusion:

The use of IoT and machine vision has brought the manufacturing industry into the smart age. IoT provides rich, real-time data by creating a connected ecosystem, and machine vision enables fast and accurate quality control by analyzing images accurately. The combination of these two technologies has reduced errors, increased productivity, and improved decision-making on an industrial scale.

Dina Software

Notification

Enter your email address to be notified of the latest articles published on the site.

Categories

Free consultation

If you need advice on software, you can contact us. Just contact us. . .

Unit 4, No. 46, Maleki St., First Square, Tehranpars

۰۲۱-۷۷۷۲۶۹۲۶