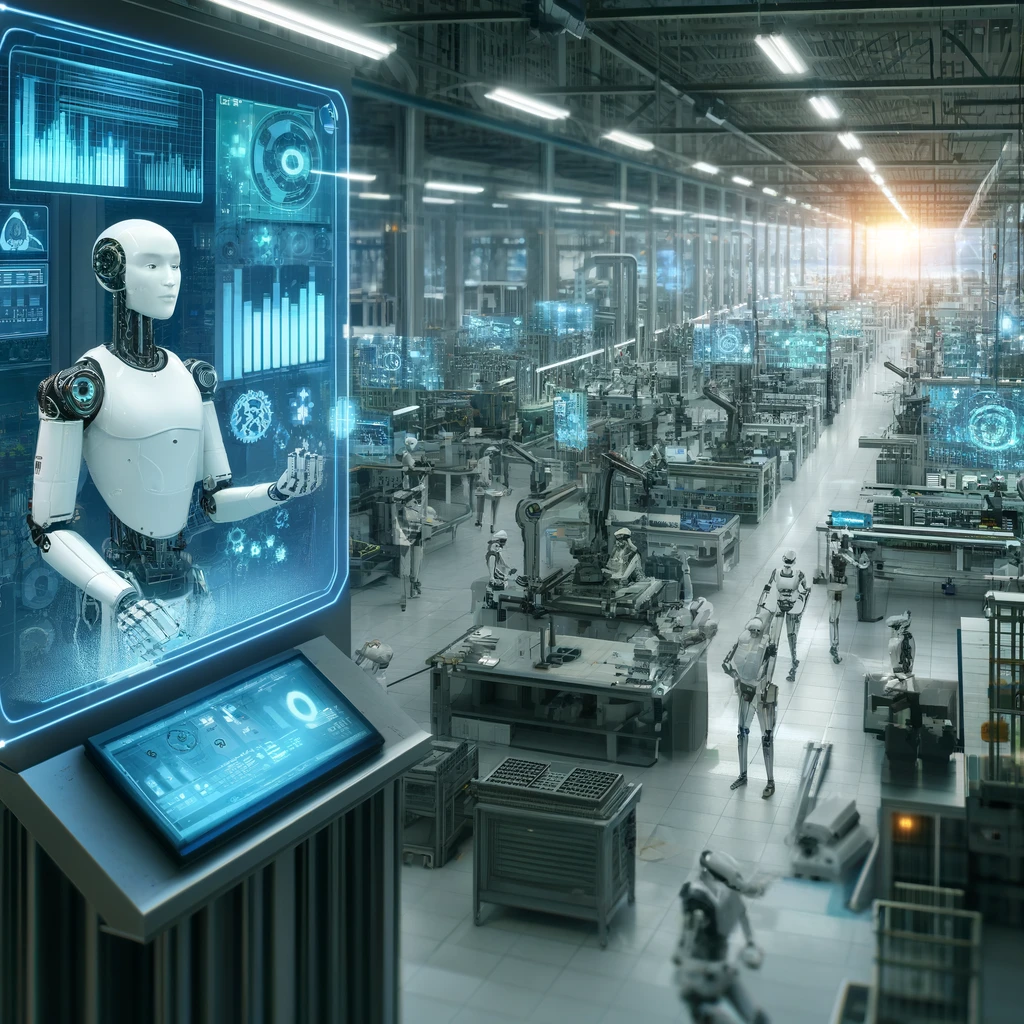

Intelligent monitoring system for the production line

Intelligent monitoring systems for production lines are technologies that automatically monitor and analyze the performance and condition of equipment and production processes. These systems use sensors, Internet of Things (IoT), artificial intelligence (AI) and big data to collect and process information.

AI in improving production performance

Artificial intelligence (AI) has become one of the key tools in improving the performance of production lines with the ability to analyze a huge amount of data and learn different patterns. In this article, some of the main roles and effects of artificial intelligence in this field are explained in more detail.

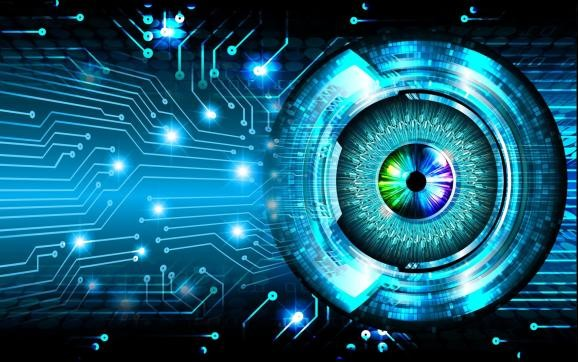

Image processing in final product quality testing

Image processing is one of the effective and advanced tools in testing the quality of the final product of factories, which can be used to automatically and accurately evaluate the manufactured products. In this process, images or videos of the product are captured by high-precision cameras and then analyzed using image processing algorithms.

What is machine vision?

Machine vision is a branch of artificial intelligence and computer engineering that allows systems to see and understand their surroundings using cameras and image sensors. The main purpose of machine vision is to process and analyze images to extract useful information. .

Industrial automation and production line data acquisition

Optimizing and increasing productivity in factories is one of the most important goals that every manufacturing organization pursues. These concepts include improving the overall performance of production processes, reducing costs, increasing product quality, and maximizing the use of available resources.

Data acquisition of equipment in the production line

Data collection from the equipment in the production line of factories is called a process during which data and information related to the performance of various equipment and machines in the production line are collected and analyzed.

Industrial automation

Industrial automation refers to the process of using technologies and automatic systems to control and manage production and industrial processes. The main goal of industrial automation is to increase productivity, reduce costs, improve product quality, and reduce the need for human intervention in various stages of production.

Computer Maintenance Management System (CMMS)

A computerized maintenance management system is a software that is used to manage and optimize maintenance and repair activities in organizations. These systems help businesses manage their assets, schedule preventative maintenance, reduce breakdowns, and generally improve the efficiency of maintenance operations.

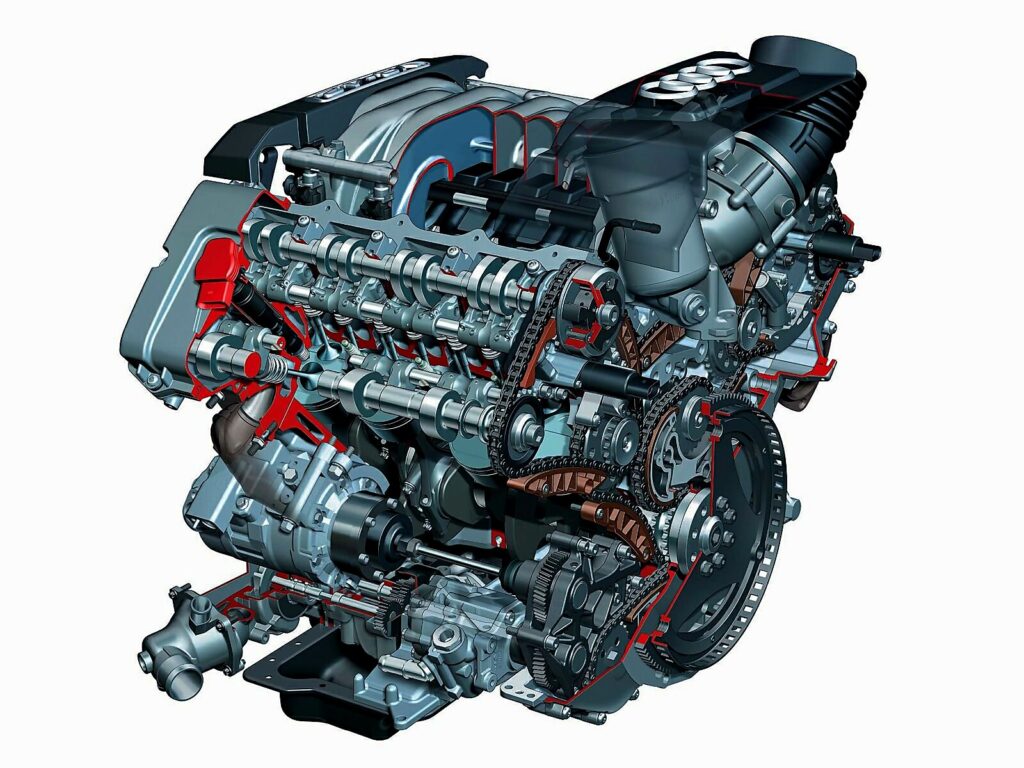

Engine test room management and automation software

Engine test room management and automation software is specifically designed for testing, monitoring and managing combustion engines and other similar equipment. These software are widely used in automotive, aerospace, power generation and research industries.

Preventing the increase of waste with production management software

Waste in the production line refers to materials that are not converted into the final product in the production process and are left as unwanted by-products or residues. Waste can be created for various reasons and can bring a lot of costs to an organization. In the following, we will explain the types of waste and the reasons for their creation