Engine test room management

And automation system

Manage the control processes of engine test rooms easily with the engine tester software

A powerful tool for engine test optimization

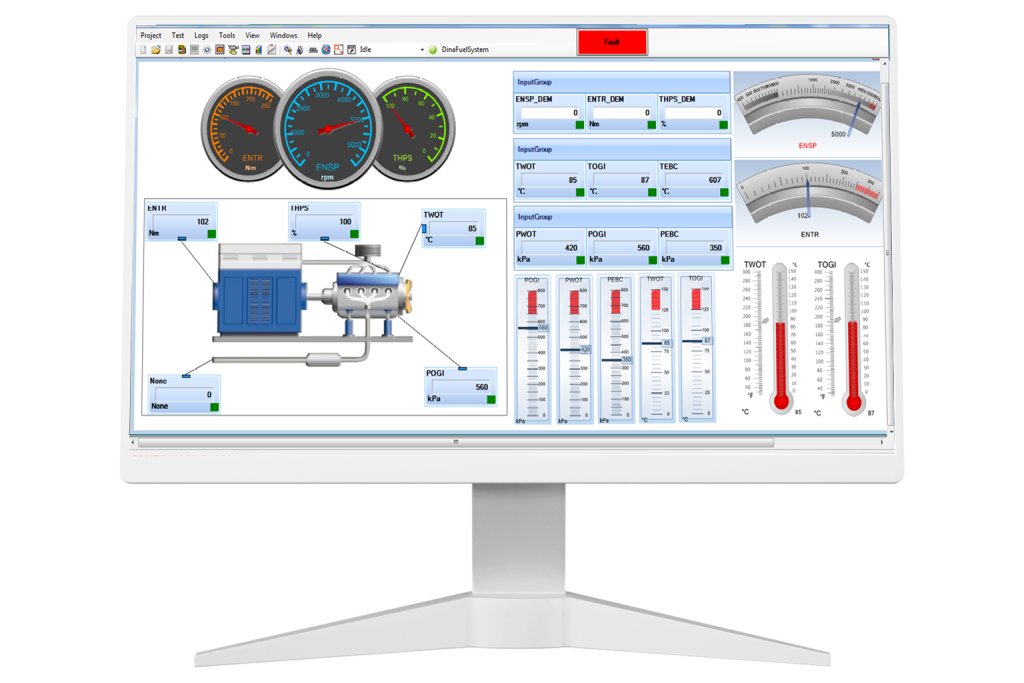

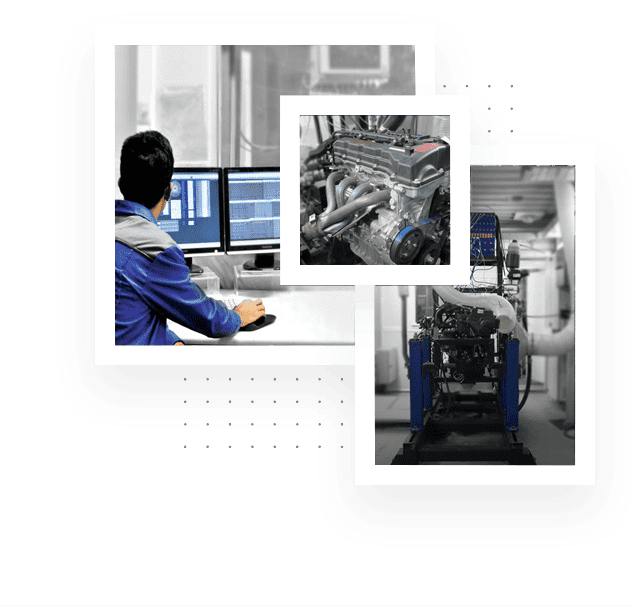

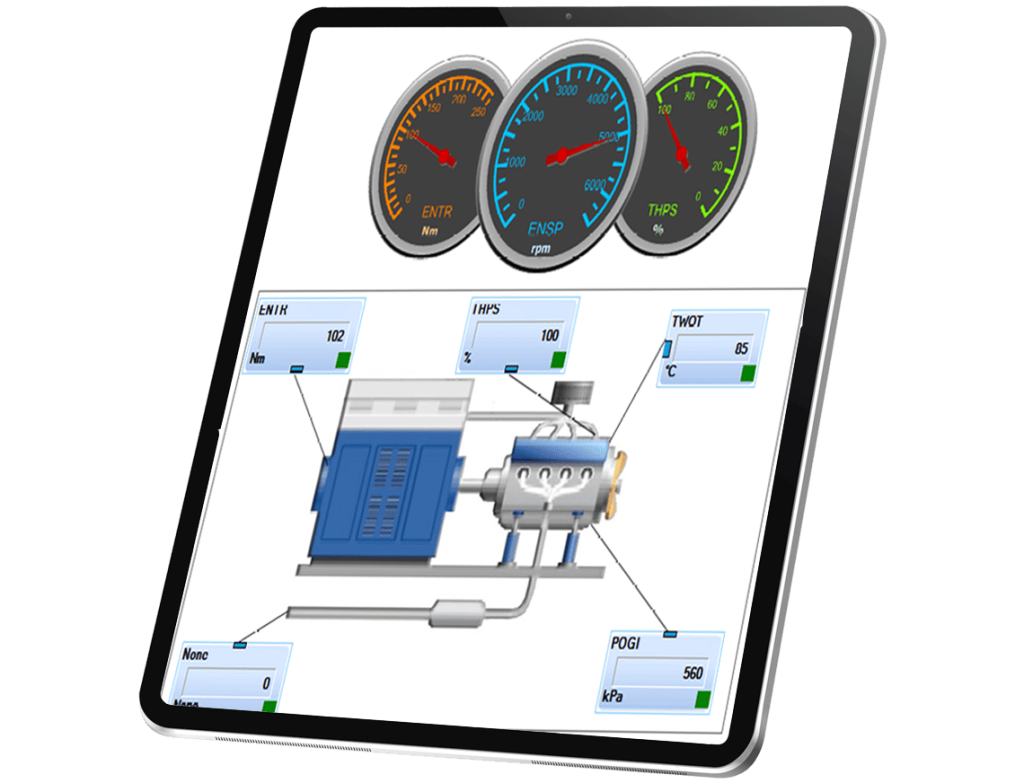

Motor Tester is a software designed to control all the activities of the motor test room designed by Dina Soft. Its main purpose is to help engineers and technicians in the automotive industry to perform engine testing more efficiently and effectively.

In the engine test room, the engine is connected with many other equipments and they are working. According to the price of the equipment and the harsh conditions of the tests, it is inevitable to use a powerful central software in order to control and guide all the activities.

Engine Tester software provides all the features needed by engine test users by using graphic and control capabilities and high communication speed. Also, in this software, it is possible to define and run the test around the clock, without the presence of the user.

مــاژولهای نرمافزار موتور آزما

با چند کلیک ساده تمام نیازهای مرتبط با اتاقهای تست را برطرف کنید.

- برنامهریزی و زمانبندی

- تجزیه و تحلیل دادهها

- کالیبراسیون و کنترل

- مدیریت و ذخیرهسازی دادهها

- اتوماسیون تست

برنامهریزی و زمانبندی:

این ماژول به کاربران اجازه میدهد تا تستهای موتور را برنامهریزی کنند، پارامترهای تست را تنظیم کنند و تکنسینهای تست را به وظایف خاصی اختصاص دهند.

کاربران را قادر میسازد تا پروتکل تست را تعریف کنند، تجهیزات تست مناسب را انتخاب کنند و شرایط تست مانند دما، فشار و رطوبت را مشخص کنند.

این ماژول معمولاً شامل یک نمای تقویم برای مدیریت زمانبندی آزمون است و همچنین اعلانهایی را برای اطلاع کاربران از آزمونهای آتی یا هرگونه تغییر در برنامه آزمون ارائه میدهد.

تعریف خودکار تمامی آزمونها و انجام آزمونها بدون نیاز به حضور اپراتور

تعریف دادهبرداری و محدودههای هشدار

تجزیه و تحلیل دادهها:

دادهها را از حسگرها و سایر دستگاههای نظارتی در طول تستهای موتور جمعآوری میکند و تجزیه و تحلیل بلادرنگ دادهها را ارائه میدهد.

و شامل ویژگی هایی برای پیکربندی و مدیریت سیستم جمع آوری داده ها، تعریف پارامترهای جمع آوری داده ها و تجسم داده ها در زمان واقعی است.

کالیبراسیون و کنترل:

وظیفه کنترل و کالیبره کردن تجهیزات تست شامل دینامومترها، جریان سنج سوخت و آنالایزرهای گازهای خروجی را بر عهده دارد.

معمولاً شامل ابزارهایی برای پیکربندی و کنترل تجهیزات آزمایشی، نظارت بر عملکرد تجهیزات و انجام مراحل کالیبراسیون برای اطمینان از اندازهگیریهای دقیق و سازگار است.

امكان ارتباط با تجهيزات جانبي

امكان ارتباط با دستگاههاي جانبي و ارسال فرمان مناسب در طول آزمونهاي خودكار

دسترسي های متفاوت کاربران در آزمون (اپراتوري، مهندسي و مديريتي)

مدیریت و ذخیرهسازی دادهها:

این ماژول ذخیرهسازی و بازیابی دادههای تست موتور، از جمله پارامترهای تست، نتایج تست و سایر اطلاعات مرتبط را مدیریت میکند. معمولاً شامل ویژگیهایی برای پشتیبانگیری و بازیابی اطلاعات، امنیت دادهها و بایگانی دادهها است.

این ماژول همچنین ممکن است شامل ابزارهایی برای مدیریت مجوزهای داده و کنترل دسترسی، و همچنین ارائه یک مسیر حسابرسی از دسترسی و اصلاحات به داده ها باشد.

مجموعهي هوشمند ثبت و دادهبرداري اطلاعات موتور با نرخ نمونهبرداری از ۱ تا ۱۰ هرتز

ثبت سريع دادهها قبل و بعد از خاموش شدن موتور در شرايط اضطرار جهت تحليل دلایل توقف و خرابي احتمالي موتور

اتوماسیون تست:

کاربران را قادر میسازد تا جنبههای خاصی از تست موتور مانند پیکربندی تجهیزات تست، اجرای اسکریپتهای تست و تجزیه و تحلیل نتایج تست را به صورت خودکار انجام دهند.

معمولاً شامل ویژگیهایی برای تعریف اسکریپتهای تست، خودکارسازی روشهای تست و زمانبندی تستهای خودکار است.

تعریف دو محدوده بالا و دو محدوده پایین روی هر کانال و یا پارامتر اندازهگیری

مجهز به قابليتهاي ويژهي تنظيم شرايط دماي آب و روغن براي آزمونهاي خاص وظيفهاي

Engine testing software modules

- Planning and scheduling

- Data analysis

- Calibration and control

- Data management and storage

- Test automation

Planning and scheduling:

This module allows users to schedule engine tests, set test parameters, and assign test technicians to specific tasks. It enables users to define the test protocol, select appropriate test equipment, and specify test conditions such as temperature, pressure, and humidity.

This module typically includes a calendar view to manage exam scheduling and also provides notifications to inform users of upcoming exams or any changes to the exam schedule.

Automatic definition of all tests and performing tests without the need for an operator

Definition of data collection and warning ranges

Data analysis:

Collects data from sensors and other monitoring devices during engine tests and provides real-time data analysis. and includes features for configuring and managing the data collection system, defining data collection parameters, and real-time data visualization.

Calibration and control:

It is responsible for controlling and calibrating test equipment including dynamometers, fuel flow meters and exhaust gas analyzers. It typically includes tools to configure and control test equipment, monitor equipment performance, and perform calibration procedures to ensure accurate and consistent measurements.

The possibility of communication with peripheral equipment

The possibility of communicating with peripheral devices and sending appropriate commands during automatic tests

Different user accesses in the test (operational, engineering and management)

Data management and storage:

Manages the storage and retrieval of engine test data, including test parameters, test results, and other related information. It usually includes features for data backup and recovery, data security, and data archiving. This module may also include tools for managing data permissions and access control, as well as providing an audit trail of data access and modifications.

Smart collection of engine data recording and data collection with a sampling rate from 1 to 10 Hz

Fast recording of data before and after the engine shutdown in emergency conditions to analyze the reasons for stopping and possible engine failure

Test automation:

It enables users to automate certain aspects of engine testing, such as configuring test equipment, running test scripts, and analyzing test results. It usually includes features for defining test scripts, automating test procedures, and scheduling automated tests.

Defining two upper and two lower limits on each channel or measurement parameter

Equipped with special capabilities to regulate water and oil temperature conditions for specific task tests

View your questions about the Motorazma software from this section

Automotive engine test room software is a special type of engine testing software that is used in the automotive industry for automotive engine testing.

This software is designed to simulate the behavior and performance of automotive engines in a test environment, allowing engineers to evaluate the performance of various engine components and systems under various operating conditions.

Automotive engine test room software typically includes a set of tools for designing and modeling an automotive engine, as well as tools for simulating engine behavior and performance. These tools can include Computational Fluid Dynamics (CFD) software, Finite Element Analysis (FEA) software, and other specialized tools for simulating engine performance.

In addition, automotive engine test room software often includes data acquisition and control systems that enable engineers to monitor and control various engine parameters during testing. This can include measuring engine speed, torque, power, temperature and other key performance metrics.

The main purpose of automotive engine test room software is to help engineers optimize the performance, fuel efficiency, emissions, and reliability of an automotive engine.

By simulating various operating conditions and evaluating the performance of various engine components and systems, engineers can identify potential issues and optimize the engine design prior to physical testing.

This can help reduce development costs and time-to-market for new vehicle models, while also improving the performance and efficiency of vehicle engines.

To install the equipment and hardware needed to control the test room, a standard 19-inch standing cabinet is needed.

This control cabinet is equipped with digital thermometer side equipment, terminal panel, uninterrupted power supply system and other protective equipment.

The industrial computer is the product of one of the reputable companies such as Advantech, which has been selected according to the test requirements and its installation conditions, and it is completely compatible with the specifications of the test engine software and other test equipment. A 22-inch monitor is used to display the software.

To protect the software during a power cut, an uninterrupted power supply system is used, which is installed directly in the control rack. This system is a product of one of the reputable companies such as American Power (APC).

Among the capabilities of the engine software, the following can be mentioned:

Automatic definition of all tests and performing tests without the need for the presence of an operator

Definition of data collection and warning ranges

Smart collection of engine data recording and data collection with a sampling rate from 1 to 10 Hz

Fast recording of data before and after engine shutdown in emergency conditions to analyze the reasons for stopping and possible engine failure

Defining two upper and two lower limits on each channel or measurement parameter

Equipped with special capabilities to regulate water and oil temperature conditions for special task tests

The possibility of communication with peripheral equipment

The possibility of communicating with peripheral devices and sending appropriate commands during automatic tests

Different user accesses in the test (operational, engineering and management)

Ability to communicate with all engine test equipment

Customizable graphic environment

Ability to define and perform automatic tests

The ability to record events after the engine shuts down

It has a method of control and non-stop communication