Machine Vision and Artificial Intelligence

Dina Software Engineering Group, with years of experience in developing industrial automation software, has expanded its activities in the specialized field of machine vision. As a key component of the industry, this technology enables precise monitoring, automatic quality control and increased productivity of production lines. We combine technical expertise, advanced equipment and up-to-date image processing algorithms with the specific needs of each industry in the path of providing intelligent solutions.

Machine vision, The precise and intelligent eye of modern production lines

Using Dynasoft machine vision systems, product quality control is carried out quickly, accurately and without human error.

This technology enables defect detection, precise measurement, barcode reading and surface feature inspection in real time.

Reliable in heavy industrial environments and adaptable to a variety of manufacturing processes.

With machine vision, ensure quality, reduce costs and get closer to global manufacturing standards.

Error-free quality control, with high accuracy and high speed

You no longer have to find problems with your eyes!

Smart, fast and non-stop production line monitoring

Applications and case studies

Artificial intelligence is a broader concept of machines capable of performing tasks that would normally require human intelligence.

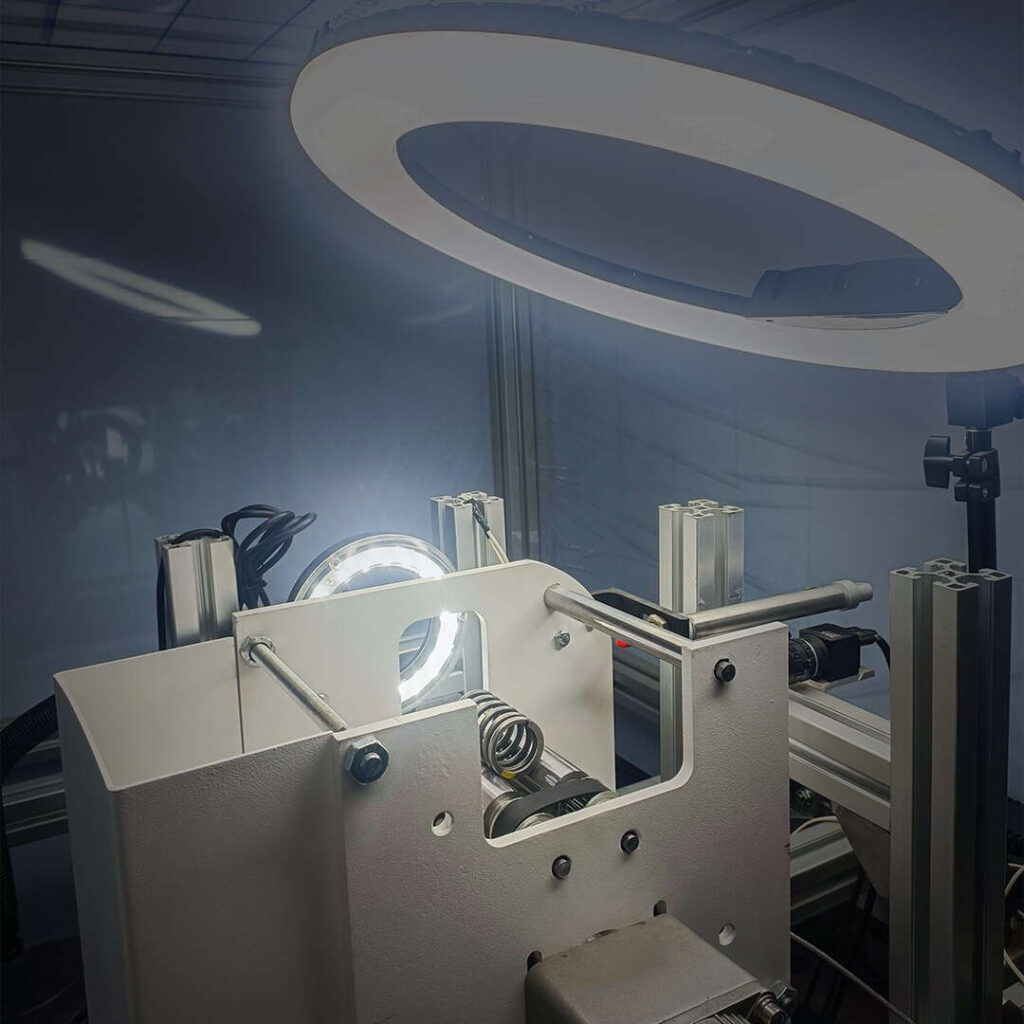

Machine vision case study for valve spring quality control

Quick reference guide for all your questions

Artificial intelligence, or AI, is the simulation of human intelligence in machines that are programmed to think and learn. The field of AI research began in the 1950s and has evolved since then to encompass a wide range of technologies and applications.

Yes, Dynasoft machine vision systems are fully customizable and compatible with a variety of traditional and automated production lines. Our engineering team will provide the best integration solution after visiting the site and reviewing the technical needs.

Our system is able to identify visual defects, dimensional deviations, assembly errors, defective codes (such as barcodes or QR codes), and changes in surface color or texture with high accuracy. This high accuracy reduces waste and increases the final quality of the product.

Many of our customers have experienced significant reductions in waste, human error, and quality control costs within 6 to 12 months of system installation. These savings quickly pay for the investment and increase profitability in the long term.

Yes, Dinasoft’s machine vision system is equipped with analytical dashboards that automatically store inspection data and provide understandable reports to production managers. This tool helps in making quick and accurate decisions.

At Dinasoft, we offer complete operator training, technical documentation, and in-person and online technical support. After launch, our support team is always by your side to ensure uninterrupted system operation.